The use of lithium-ion batteries in portable electronics is trending nowadays because of its advantages over other types of batteries. However, before the lithium-ion batteries are used in powering technological devices they undergo testing processes and validation, which ensures that the possibility of risks is mitigated.

These testing processes are important in regulating one of the important issues associated with lithium-ion batteries, which is thermal safety. This is because electronics nowadays requires the use of simple and lighter batteries with a higher capacity of powering the device for a longer period. This has increased the demand in the marketplace of producing lithium batteries to the highest level by creating dangerous cases due to the increased amount of transportation along with people handling it.

Here various reasons why the lithium-ion battery undergoes strict safety tests:

- Transportation testing

All manufactured lithium-ion batteries undergo the transportation testing process according to the safety standard. During the transportation testing process, the battery is subjected to a condition of extremely different temperatures that mimic the effects of shipping environments. The testing process can either shock, impact, or salt testing depending on the stability of the batteries and cells.

- Safety and certification testing

The safety and certification testing of lithium-ion batteries involves a wide range of sustainability testing, such as extreme temperature, voltages, and currents. This type of testing ensures that any lithium-ion batteries, which undergoes the process will be safe to use based on the battery safety certificatory standard.

- Electromagnetic testing

Electromagnetic testing ensures that any device, which is powered by lithium-ion batteries will not mal-function under a high level of electromagnetic interference. The testing process ensures that all devices powered by lithium-ion batteries will not create any electromagnetic interference itself (EMI).

Even with all these testing processes of lithium batteries, there are more things to consider that includes:

The wide application of lithium battery in life

Lithium-ion batteries are widely used in technological electronics, because of its improved value and compatibility on most electronics. The use of lithium batteries can be seen from smartphones that use small batteries to larger batteries as seen on automobiles. Lithium-ion batteries have gained the trust of many people globally due to its versatility and efficiency.

Lithium-ion batteries are widely used in technological electronics, because of its improved value and compatibility on most electronics. The use of lithium batteries can be seen from smartphones that use small batteries to larger batteries as seen on automobiles. Lithium-ion batteries have gained the trust of many people globally due to its versatility and efficiency.

The sizes of lithium-ion batteries differ from each other along with its shape which indicates the amount of power it can generate. Some of the applications of lithium-ion batteries include:

- UPS

- Mobile phone, laptops, and wristwatches

- Energy systems

- Vehicles etc.

Among the above-mentioned application of lithium-ion batteries in technological devices, there are other uses of this battery, which benefits users by boosting the power usage of technological devices.

The working principle of lithium battery

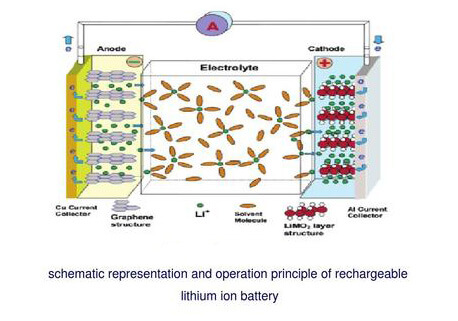

The structural composition of the lithium-ion batteries varies from each other. Even as at that, independent of their sizes, the lithium-ion batteries are all made with components such as anode, cathode, separator, and electrolyte. The electrolyte is lithium salt in an organic solvent that’s unstable requiring the combination of both lithium and oxygen together to produce a stable compound known as lithium-oxide.

The cathode inside the lithium battery pack is what determines the features of the battery. This is what indicates what the battery capacity and voltage will be based on the lithium-ions material coated on the cathode. The higher the lithium ions material coated on the cathode the bigger the battery capacity and voltage will be. Another thing that’s inside the lithium-ion battery is the separator, which ensures that the cathode and anode are separated from each other for safety purposes in the entire system.

Why does the lithium battery explode

There are several factors, which will make a lithium-ion battery explode. In most cases, the problem is short-circuiting when the separator fails to limit the cathode and anode inside the battery from touching each other. Once the cathode and anode inside the lithium-ion battery touch each other, it will start to overheat both the battery and electronics components.

There are several factors, which will make a lithium-ion battery explode. In most cases, the problem is short-circuiting when the separator fails to limit the cathode and anode inside the battery from touching each other. Once the cathode and anode inside the lithium-ion battery touch each other, it will start to overheat both the battery and electronics components.

The lithium-ion battery separator failing to function properly is a rare result, especially if the lithium-ion battery was initially subjected to a certified testing process.

Here are the reasons why the battery separator might fail:

- Bad design of the battery

If the battery is poorly designed without fixing the separator perfectly in its stipulated area. It will likely cause the battery to explode as the battery components expand and extract when it’s being charged, allowing both the cathode and anode to touch. To prevent this, batteries are tightly built in such a way that the separator will remain fitted after the expansion and extraction of the batteries components.

- External factors

External factors affecting a lithium battery can cause it to explode, whether it’s weather conditions or other physical effects. A very hot weather condition can cause the battery components to overheat causing it to explode. Using a charger that doesn’t match the stipulated requirement for charging a lithium battery will probably make it explode.

Even though lithium batteries tend to fail and explode on rare occasions. The testing process of lithium-ion batteries is very safe to use in electronic devices, once they undergo accurate testing processes. Even after these testing processes, battery manufacturers always ensure that all their development is properly safeguarded to prevent failure.

The importance of lithium battery safety testing

There are a series of benefits that comes with the use of lithium battery safety testing, which includes:

- Low maintenance

Unlike other types of batteries that require maintenance by the regular increment of its water level and more. The lithium batteries don’t require these types of maintenance but only requires the user to keep it under specified environmental condition.

- Long-lasting

The lithium-ion batteries can last for a longer period without any side effects or failure for as long as 8 years or more. This ensures that all electronic devices using lithium batteries can last for a longer period.

- Fast charging ability

The lithium-ion batteries can be fully charged in a little amount of time, due to its fast charging ability. This makes it possible for electronic devices with high capacity lithium-ion batteries to be fully charged in a short period.

How to test the lithium battery safety

The safety testing for a lithium battery is the process where the battery is placed inside the environmental testing machine that mimics different external temperature conditions. A single specimen of the lithium battery placed inside the testing machine will likely turn out damaged after each testing phase because inside the environmental testing machine the temperature can either go from extreme cold to hot depending on the testing method initiated. The stages of the testing phase involve voltage testing, internal resistance testing, etc.

The safety testing for a lithium battery is the process where the battery is placed inside the environmental testing machine that mimics different external temperature conditions. A single specimen of the lithium battery placed inside the testing machine will likely turn out damaged after each testing phase because inside the environmental testing machine the temperature can either go from extreme cold to hot depending on the testing method initiated. The stages of the testing phase involve voltage testing, internal resistance testing, etc.

During the testing process, all of the results achieved are meant to be recorded as produced by the machine during each testing phase. These records are what will be evaluated after the testing process to determine how the lithium battery will react in certain environmental conditions.

There are many standards used in lithium battery safety testing, such as IEC 62133, IEC 62619, ECE R100, UL 1642, UL 2580, UN 38.3, etc. Depending on the content of the test, the corresponding standards are different, so it is necessary to know what kind of lithium battery safety test you need to test. Most of these standards require a series of machines, such as servo computer battery crush tester, temperature control battery short circuit test chamber, thermal abuse test chamber, battery crush nail penetration tester, hock test system, thermal runaway test machine, etc. Lithium battery safety testing often requires the use of environmental chambers, such as double-deck high and low temperature test chamber, the walk-in chamber for rapid rate temperature or humidity test, the walk-in chamber for complex salt spray test (Temperature controllable), the walk-in chamber for sand dust-proof Test, etc.