Comparison of Asbestos & Polyurethane Foam

At this time, you may have questions. Why Polyurethane foam will replace asbestos in the future?

Significant effect

Polyurethane foam has many advantages over asbestos. For example, the foamed filling can be densely filled depending on the size and shape of the void. In addition, Polyurethane foam has low thermal conductivity and good thermal insulation.

Safety

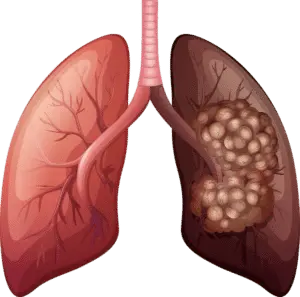

It is worth noting that on October 27, 2017, the list of carcinogens published by the International Agency for Research on Cancer of the World Health Organization was initially compiled and referenced. Asbestos was included in the list of carcinogens. With the strengthening of environmental awareness and the compulsory requirement of the state, the implementation of the policy prohibiting the use of asbestos. In the future, Polyurethane foam insulation material will definitely replace asbestos and become a new type of insulation material for environmental testing equipment.

At this time, you may have questions again. Why is asbestos harmful? So many manufacturers still use it?

Price

in terms of price, the Polyurethane foam material is relatively expensive compared to asbestos. Therefore, many manufacturers still choose asbestos as insulation materials in order to save costs.

Craft

Another major reason is process problems. Once the Polyurethane foam is shaped, it is difficult to know, especially the instruments, pipes, and circuit lights after foaming. If it is very troublesome during troubleshooting. This is also why it is widely used in refrigerators and other thermal insulation fields, but it is not favored in the constant temperature and humidity industry.

Summary

It is worth noting that our constant temperature humidity test chamber adopts flame retardant high strength PU Polyurethane foam insulation material. And our constant temperature and humidity equipment meet many international standards. As shown below:

- IEC68-2-1

- IEC68-2-2

- IEC68-2 -3

- IEC68-2-30

- IEC68-2-14

- MIL-STD-810D