The salt spray method is a popular process, which ensures that materials and products are tested for corrosion determining its ability to adapt to certain environmental conditions. This process requires the use of a testing chamber to check the corrosion resistance of different products or materials surface. The use of the salt spray method applies to certain metallic materials and products, which can be metals, alloys, and others.

Products that are finished with a surface coating of metallic will require salt spray testing to determine the degree of corrosion. During the testing period, the salt spray produces a corrosive attack on the material to evaluate its degree of sustainability or amount of damages the material incurs under certain conditions. The salt spray testing period depends on the material’s ability to resist corrosion, which can be due to its coating or finishing features. This means that the higher the material’s ability to resist corrosion, the longer it will take the testing process to complete (appearance of corrosion).

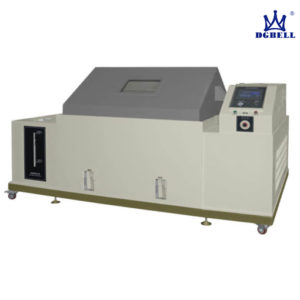

What is the salt spray test chamber?

The salt spray test chamber is specifically built for testing the ability of materials to resist corrosion. The salt spray test chamber is designed to utilize a powerful component that includes a sensor to determine the temperature of the material during the testing process. The salty spray test chamber comes with a programmed control that can be either analog or digital for the purpose of indicating targeted temperature. The machine-testing sensor reads the temperature value of the material as the test goes on while providing results to the operator. In the salty spray test chamber, the programmed controller provides information that can be customized and edited based on the user’s intention, such as creating testing cycles, temperature profiles, and more.

The salt spray test chamber makes use of a certain amount of salt-water (NaCl) solution along with pressurized air from the spray nozzle to create a corrosive environment inside the chamber. This corrosive environment will include salt-water fog that will affect the specimen before providing results based on each condition it undergoes.

In the salt spray test chamber, a certain specimen can be limited to testing due to its size and type of material. In most cases, larger chambers are mostly preferred when testing bigger or smaller specimens in batches as it will provide enough testing space with accurate results. All salt spray test chamber has the purpose of creating a corrosive environment by cycling through ranges of temperature value to test product efficiently.

Where can the salt spray test chamber be used?

There’s no limitation to where you can use the salt spray test chamber. Once there’s enough space and a normal temperature rate around the environment, you can configure and use the salt spray test chamber while making sure that it’s perfectly closed during the process to avoid creating pollution and jeopardizing safety.

How to use the salt spray test chamber?

To get an accurate result after testing, the specimen will need to be properly attached to the test machine. It requires the user to do everything the right way. The first step for the salt spray testing is getting the specimen ready. How the specimen will be tested depends on the nature of the specimen such as shapes, sizes, and it’s coating features.

Testing materials can be placed in the specimen carrier area or comfortably hanged with a thread on the fixed rod inside the chamber to ensure an accurate testing process. After placing the specimen, the testing chamber is required to be closed, with the needed testing parameters like temperature value, and others set. In most cases, the result of each test in the chamber depends on the technique used during the testing period.

Why do you need to pay attention to when operating the salt spray test chamber?

The operator managing the salt spray chamber during the testing period because of several reasons that include safety etc. During the testing process in the salt spray test chamber, the material undergoes ambient condition testing that will require the attention of the operator. The operator is required to be available at the initial stage of placing the specimen on the carrier area inside the chamber perfectly. This will ensure that the specimen doesn’t fall off the test area during the operation.

The salt spray test chamber performs testing tasks based on the operator’s added command. It means that once a process has been activated, the operator is required to closely monitor the whole process while recording necessary attributes, ensuring everything goes as required.

Therefore, the operator is required to pay extreme attention when testing specimens on the salt spray chamber for safety. There’s no doubt that the specimen might end up damaged after the testing process, due to the amount of corrosion incurred. However, without the operator’s attention during the testing process, the machine will likely breakdown after running for a long period, causing serious damage.

How to choose the salt spray test chamber?

As a business owner that owns a manufacturing business that might require the use of salty spray testing chambers for testing products and materials corrosion resistance. There’s no doubt that the use of the salt spray test chamber in testing your products will boost your initial goal which might be producing risk-free developments. However, the complex task normally comes when choosing the appropriate test chamber. Getting the perfect salt spray test chamber for testing of your business products is not an easy task, as it requires you making some considerations, which includes:

- Salt spray test chamber size

When buying a salt spray test chamber, the accurate size for the products and material you want to test is always the first thing to consider. If your business manufacturers products that are in sizes, then buying a smaller test chamber can fulfill your requirement. However, if there are bigger materials and product developments from your manufacturing company, the larger chamber will be a better choice for testing. DGBELL has a different size from the salt spray test chamber.

| Model | BE-CS-60 | BE-CS-90 | BE-CS-120 | BE-CS-160 | BE-CS-200 |

|---|---|---|---|---|---|

| Test Space W x H x D(mm) | 600x400x450 | 900x600x500 | 1200x1000x500 mm | 1600x1000x500 | 2000x1200x500 |

| External Dimension W x H x D(mm) | 1070x600x1180 | 1310x880x1280 | 1900x1300x1400 | 2300x1300x1400 | 2700x1500x1500 |

| Lab Volume | 108L | 270L | 600L | 800L | 1440L |

| Brine Tank Capacity | 15L | 25L | 40L | 40L | 40L |

| Power Supply | AC220V,15A | AC220V,15A | AC220V,20A | AC220V,20A | AC220V,30A |

| Test Equipment Temp. Range | RT~55℃ | ||||

| Pressure Tank | RT~70℃ | ||||

| Temperature Fluctuations | ≤±0.5℃ | ||||

| Temperature Uniformity | ≤±2℃ | ||||

| Temperature Precision | ±1℃ | ||||

| Spray Pressure | 1.00±0.1kgf/cm2 | ||||

| Lab Relative Humidity | Above 85%H.R | ||||

| Spray Way | Continuous or intermittent type spray(optional) | ||||

| Spray Quantity | 1.0~2.0ml/80cm2/hour | ||||

| Safety Protection Device | Current discharge protection, over pressure protection, over temperature protection, over load fuse protection. | ||||

- Types of material to test

The type of materials or products your company develops will serve as the key to what type of corrosion test machine your business needs. Some testing machine only tests certain products and materials depending on what’s used in manufacturing it.

- Salt spray test chamber price

Finally, another thing to consider when choosing the perfecting test chamber is the Salt spray-test chamber price. There’s are different types of salt spray chambers and each of them provides different purposes in testing different sizes of products and materials. However, when it comes to price, there’s no fixed amount as it’s often based on the testing machine feature and its ability to determine to create a corrosive environment for test after configuration.

With the option of buying a salt spray-testing machine from a popular salt spray test chamber manufacturers, all your innovation and development will be thoroughly tested. With all the above considerations in choosing a salt spray test chamber, there’s every possible reason that you won’t find it difficult to get the perfect testing machine for your business. It will help boost your business developmental process to its peak as they produce durable and certified products or materials.